Details

The insane fuel volume requirements of todays ‘big power’ GTR builds makes us cringe, and the alternator cry! Piling pumps on pumps on boosters is a recipe for disaster with so many potential failure points, and the 70-80 amps of current draw doesn’t make for a happy electrical system. It’s not rare to see three Walbro ethanol compatible pumps, with one or two of them being run at 20+ volts with voltage boosters.

The above scenario is common at 1600whp and higher, on ethanol, and still won’t support more than about 1850whp (3 pumps and 2 boosters).

For more power, being ethanol or methanol, a mechanical fuel pump is the only option.

Generally speaking, putting a mechanical fuel pump at the front of the car, to pull fuel from a tank in the rear of the car, is about as bad an idea as it gets. Fuel pumps are designed to be pressure fed, by at least gravity. Restricting fuel to the inlet side of a fuel pump is a sure fire way to cause cavitation, among other things.

The GT1R mechanical fuel pump kit solves all of the common problems with mechanical pumps.

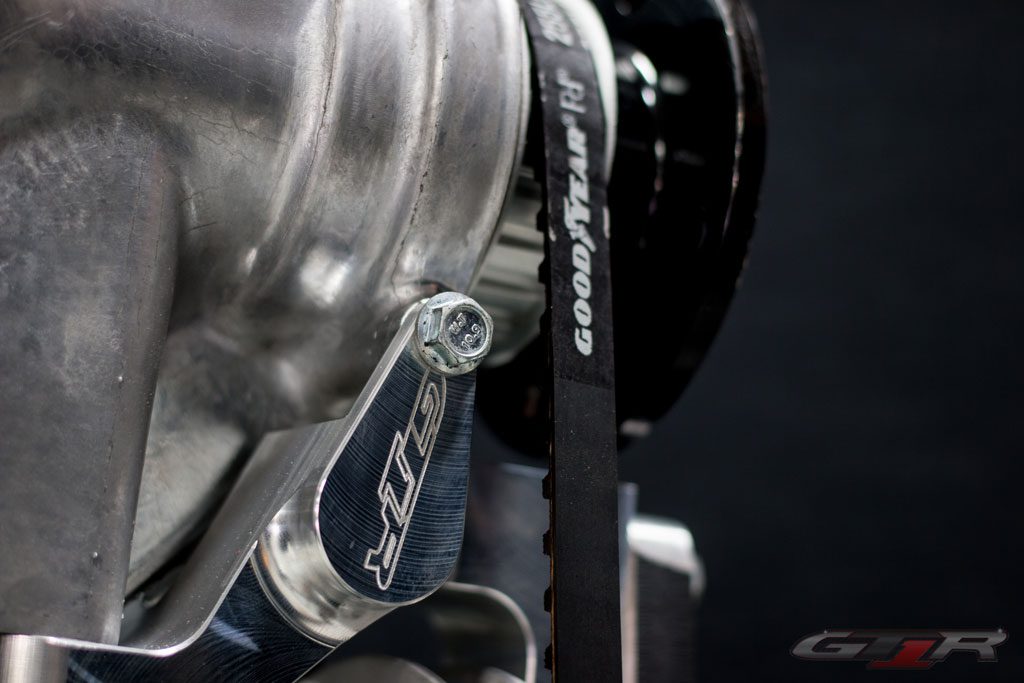

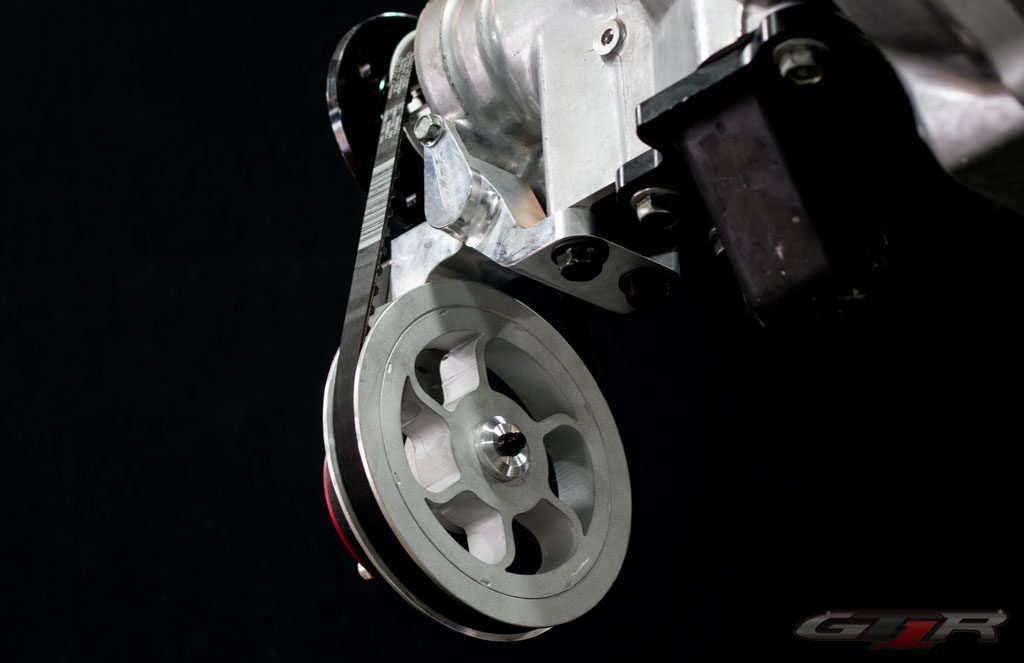

We start with a custom drive pulley to fits on a modified OE bellhousing. This drives our cable pulley, which drives a cable to the rear of the car, where the pump resides. A CNC bracket attaches the cable drive pulley to the bellhousing.

Since the fuel pump is in the rear of the car, mounting is flexible to a certain degree with the supplied cable. Custom cable lengths are available for pump placement pretty much anywhere you prefer. The pump should be mounted reasonably close to the tank, and it should be gravity fed. This eliminates the need for an electric fuel pump for priming the system, and ensures good pump supply under all conditions.

The pump is a Kinsler Fuel Injection Tough Pump 2. We offer two different models (pricing is the same), the TP900 and TP1300. We recommend the TP900 for ethanol applications and TP1300 for methanol applications.

The great thing about a mechanical fuel pump is that flow is proportional to engine speed, so it’s the lowest at idle, and max at max engine speed, much like horsepower, which is what determines your fueling needs.

The other great thing about a mechanical fuel pump is that flow does not decrease with fuel pressure, like it does with an electric fuel pump. The reason for this is that the pump speed doesn’t change relative to fuel pressure, which happens with an electric pump, and it’s what causes the flow to decrease with fuel pressure (with boost).

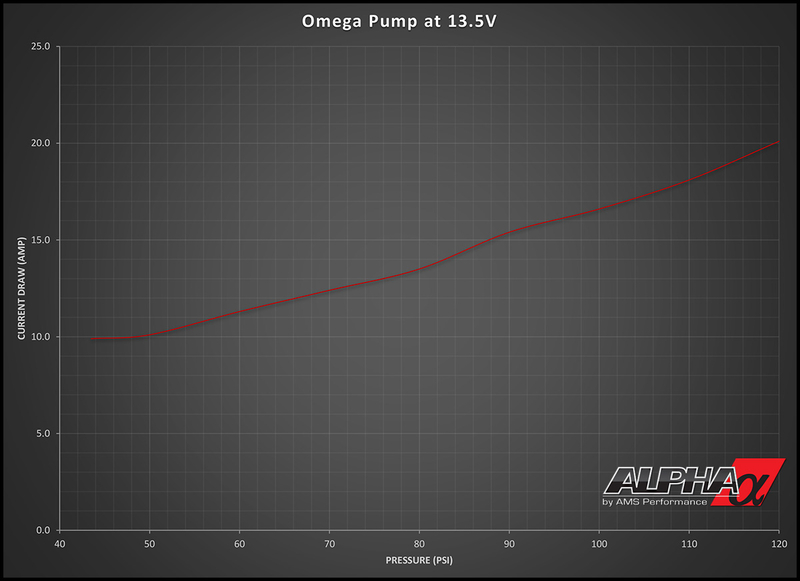

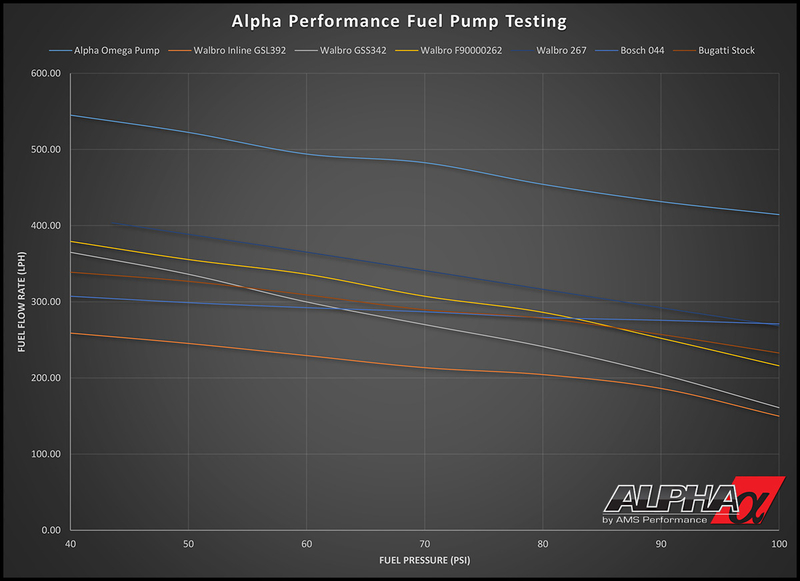

For reference, the very popular Walbro F90000267 pump (their ‘485’ pump), flows 248lph at 90psi and 12.5 volts (typical voltage AT THE PUMP).

The TP900 flows 2486lph at 9000 engine RPM (4500 pump RPM). This is the equivalent to 10 of those Walbro pumps!

The TP1300 flows 3528lph at 9000 engine RPM (4500 pump RPM). This is equivalent to 14 of those Walbro pumps at 90psi fuel pressure!

To take things a step further, this is all based around running a very low base fuel pressure of about 40psi, in order for the electric pumps to keep up. The injector flow rate is relative to the base fuel pressure (differential pressure), but the pump sees that, plus the increase from boost (1:1 ratio), plus flow losses at the system. So an application running 40psi base pressure and 40psi of boost, often has at least 85-90psi at the pump once you account for flow losses in the system (pressure drop from pump to injector).

And ID1700 flows 1725cc/min at 43.5psi, but it flows 2640cc/min at 100psi! Being able to increase the base fuel pressure of the system allows for significantly more power potential from a set of injectors.

The mechanical fuel pump will easily supply 200psi, so running a high base fuel pressure isn’t a problem at all to the pump, and on methanol it’s absolutely necessary to get the fuel volume required!

It all sounds insane, but for 2500+hp on methanol, you’re going to use over 7000cc/min per cylinder. That’s 41,000+cc/min, which works out to 2480lph, at 160+psi fuel pressure (pump pressure)!

The kit consists of all drive pulleys, machined and installed, CNC mounting bracket for pulley adjustment, belt, cable, fuel pump with in/out fittings, universal fuel pump mounting bracket (needs to be fitted to chassis where desired).

*The TP900 needs a min of a -12 feed line from the tank/cell. The TP1300 needs a -16 line.

*This kit requires bellhousing modification. The modification is included in the kit cost, but you need to send us your bellhousing. Alternatively, we can supply a new OE Nissan bellhousing for an additional cost, saving the time and hassle of sending us your housing.

_Related Products

Comments & Reviews

You must be logged in to post a review.

Reviews

There are no reviews yet.