GT1R E5LM Hanger | T1 02.01.04

T1-spec R35 GT-R Brushless Pump In-Tank Fuel Hanger

Remember the days of multiple fuel pumps, multiple voltage boosters and having to run ¾ tank of fuel? We do too, glad they’re behind us!

The OE’s go to great lengths to ensure as much fuel as possible can be used from the tank between fill ups. They do this by providing a ‘bowl’ the pump pulls fuel from and using siphon jet pumps to move fuel from various places in the tank to that bowl.

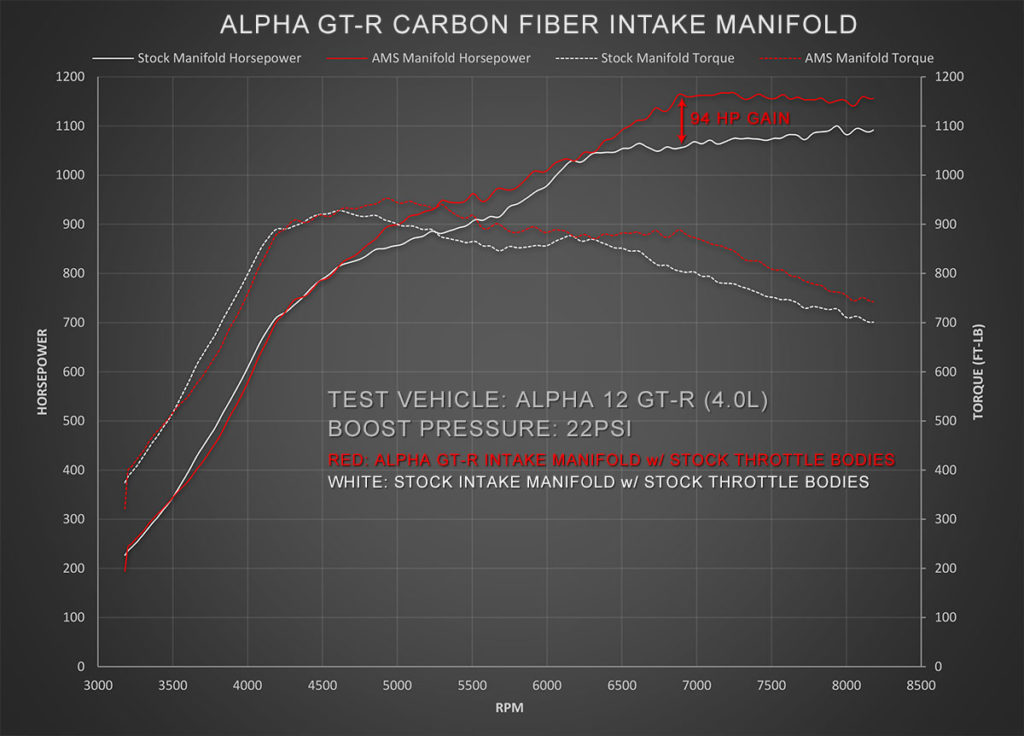

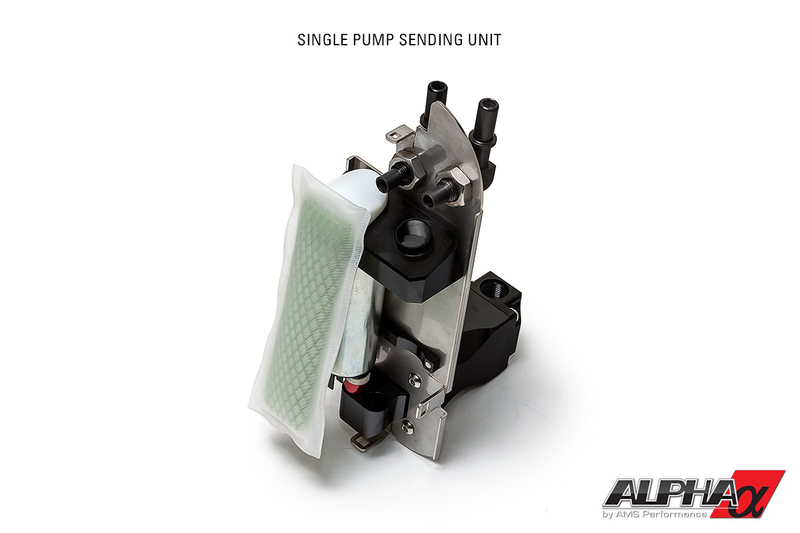

Our new GT1R E5LM Fuel Pump Module paired with the Injector Dynamics FPS1100 will allow a bit over 2,000whp on ethanol from a SINGLE fuel pump, with relatively low fuel tank levels, along with various pump speed control options and CAN diagnostics. For those with even loftier goals, this single pump system can easily be converted to a dual pump system for less than $900. With the dual pump configuration an incredible 2,700whp on ethanol is attainable!

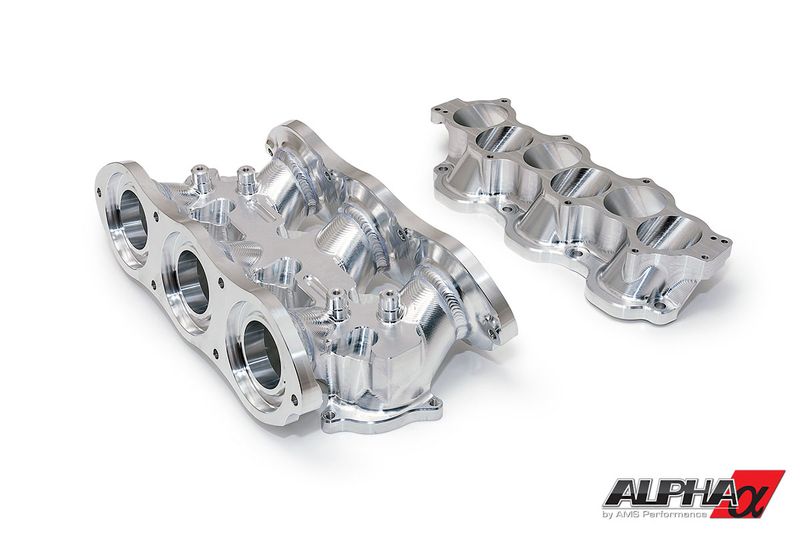

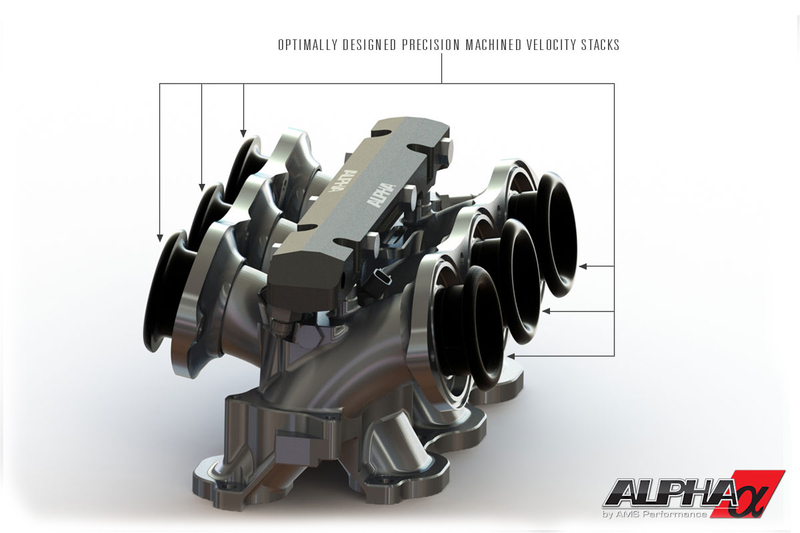

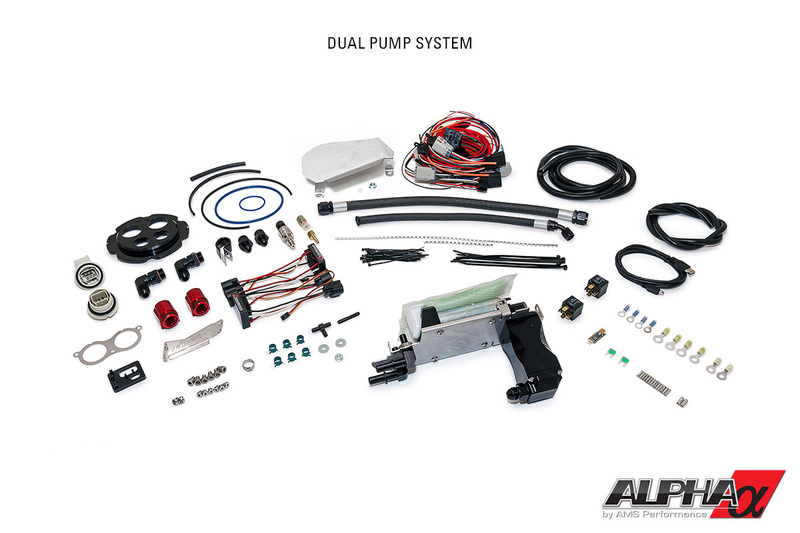

The fuel pump module retains the lower plastic OE ‘bowl’, and includes a new upper assembly, in-tank fuel filter, fuel tank lid, internal check valve, and necessary lines and fittings for the lid and inside the tank.

*Note – you will need a couple parts from the OE plastic module.*

The in-tank filter is much more a hassle to change than an external filter, so we use a 40-micron filter there. This isn’t fine enough to protect the fuel injectors, but it’s good to catch the larger stuff that would otherwise end up in the finer filter, and since there’s not much of that, it’ll very rarely need serviced.

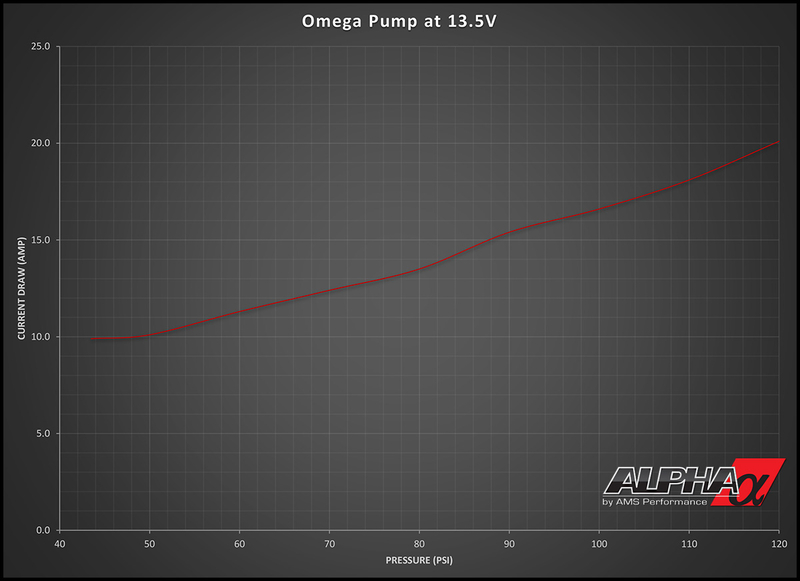

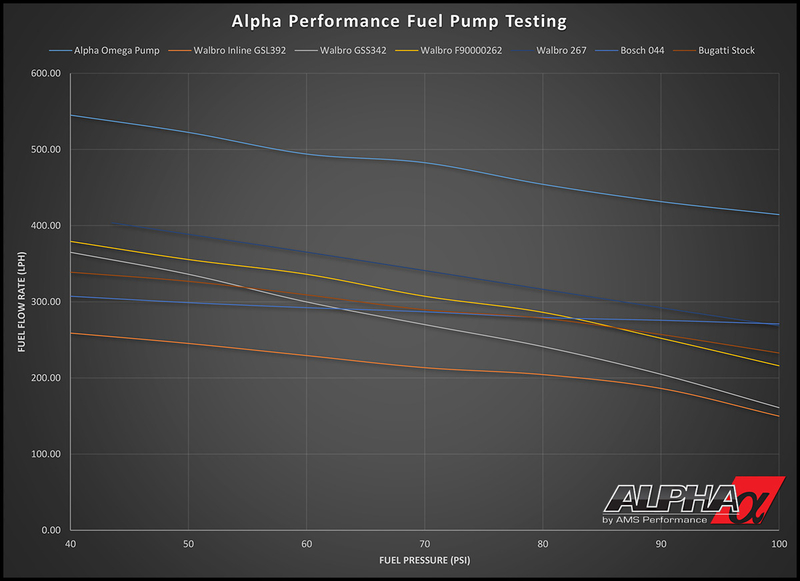

The heart of the system is the Injector Dynamics FPS1100 (consisting of the BPC100 pump controller and E5LM fuel pump). This brushless fuel pump and controller combo is very unique when compared to others on the market. The microprocessor-based pump controller monitors pump speed and maintains a target flow rate even as operating conditions change. It does so by powering the pump from an internal power supply, making pump flow independent of battery voltage and fuel pressure across a broad operating range. This is in sharp contrast to conventional designs where flow is a function of system voltage and fuel pressure.

Consider that while a pair of 500 l/h conventional pumps may flow a combined total of 1,000 l/h at 3 bar and 13.5 volts, this can drop as low as 700 l/h at 30 psi of boost. That same 30 psi of boost at 4 bar static pressure and 12.0 volts reduces the flow even further, as low as 500 l/h – less than half the advertised value.

Note that this is not a defect, or misleading marketing, it is simply the nature of conventional pumps.

In comparison, the BPC100 is capable of maintaining 1,100 l/h under the conditions above, and more. How about 5 bar static pressure, and 5 bar boost with a broken alternator belt and a failing battery delivering only 8 volts at the 1,320?

Still…1,100 l/h! When we say 2,000whp on ethanol, that’s a real number, independent of boost and voltage (so long as you’re over 8v and below 150psi of fuel pressure!)

To make the install as painless as possible, we also offer a mostly plug and play wiring kit. This kit takes care of the fusing, power and ground supply wires, control wires (plugs in where the OE Fuel Pump Control Module was) and CAN diagnostics (if using a Motec M1 ECU).

Comments & Reviews